Prototyping

Testing designs and mechanical features is a critical part of the product development process. I believe that breakthrough innovation can only be achieved by following and heuristic approach that is based on testing prototypes and observing users interactions. Every prototype testing will provide insights and learning that will reduce risks, increase performance and improve the consumer experience.

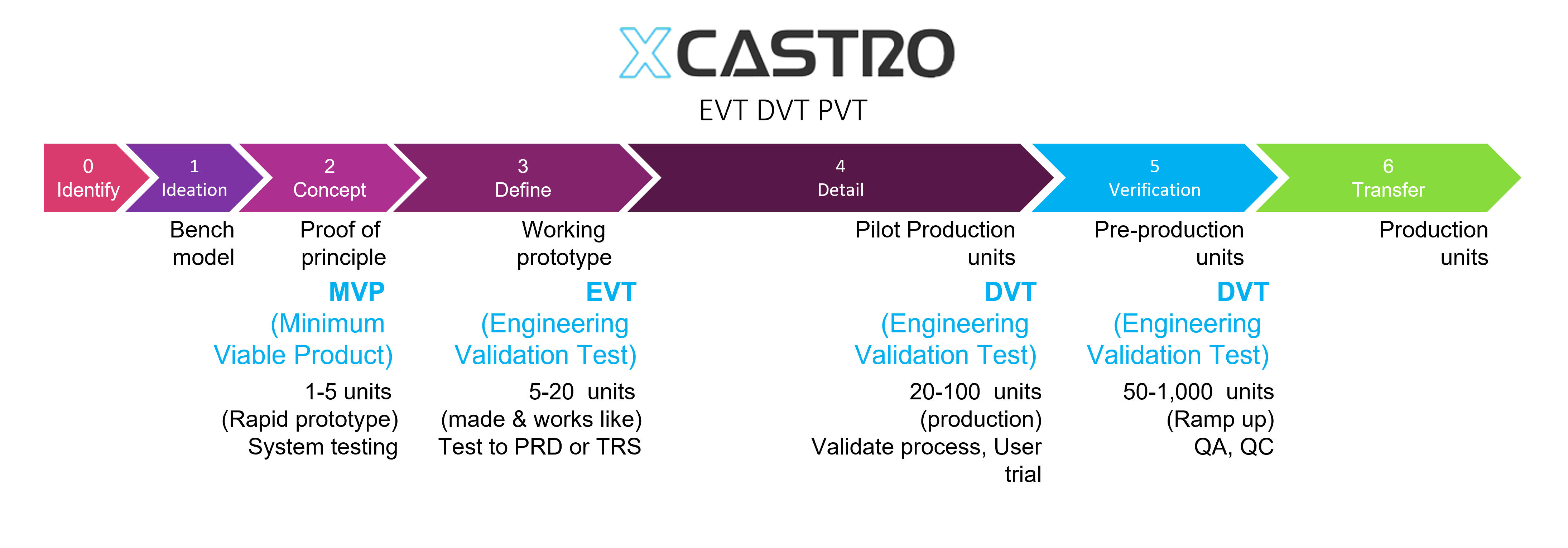

My approach follows an iterative process, where low resolution and bench models are produced on early stages, which are inexpensive and fast to create. As the product evolves, the resolutions, quality and complexity of the prototypes is increases, until we reach the final production model.

The ideas is to test quickly in early stages the more critical aspects of the design to then optimize the design on the last stages.

The list bellow shows a brief description of each type of prototype that I use:

Bench models

- Form – Foam or 3D printed models that will explore shape and form (if product is large, this could be made to scale)

- Subsystem functional - Mechanical bench test rigs that will demonstrate a specific function. Often are larger than the final product and are made of “of-the-sheld” parts. Should be easy to modify.

Proof of Principle

- Looks like – Non-functional prototype that will look as the final product. Are often made of Vac casting or 3D printed parts that are painted.

- Works like – Functional prototype that will not look like the final product and might be larger. Uses a combination of 3D printed, CNC and off-the-shelf components.

Working Prototype

- Looks and works like – A functional prototype that is the same size, form, and finish of the final product. However, it is made of prototyped parts (CNC, 3D prints or vac casting) that may not achieve the same performance as the final product.

Pilot production

- Made like – A functional prototype made with tooled parts in the final materials. However, the caseworks and aesthetic components might still be made of prototyped parts (CNC, 3D printing or vac casting)

- Made and looks like – This is a fully functional prototype that is made of all the final components but assembled by hand. This is the 1st series of fully functional products sometimes called the “golden samples”

Helping creat your prototypes

I work with a large spectrum of companies in supporting them on the selection of the right level of prototype for each stage, overseeing the prototype construction and testing them

I have a vast network of prototyping suppliers and have access to a wide range of prototyping processes to create different levels of models.

.jpg)